Proprietary Technology

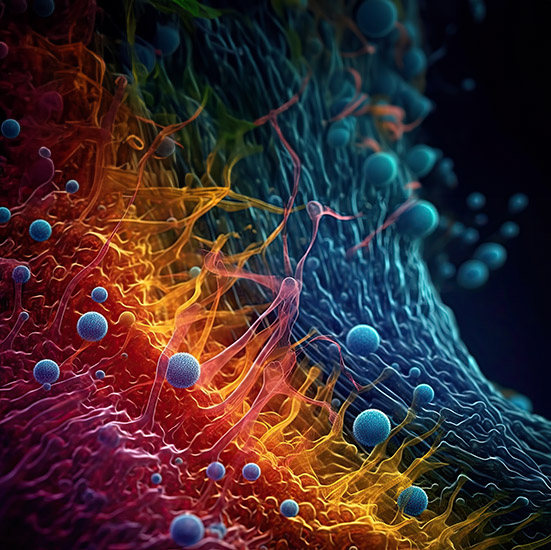

Proprietary Strains for Fermentation

Utilize unique bacteria and fungus strains for optimal production of enzymes, peptides, growth factors, amino acids, and vitamins through media optimization

Low Heat Metabolite Impregnation Technology.

This technique embeds metabolites into a carrier, preserving their viability through advanced Drying Technology. Instead of typical spray drying (180°C – 200°C), RDL employs a proprietary drying method at 50°C. It ensures all metabolites remain active in the additive, offering a superior delivery method for maximal animal benefit.